Safety Three R's Quiz

Question 1

What is the first R in the workplace safety process?

Question 2

According to the article, what percentage of preventable accidents were stopped by frontline workers' immediate actions?

Question 3

What is the MOST important reason to report hazards according to the article?

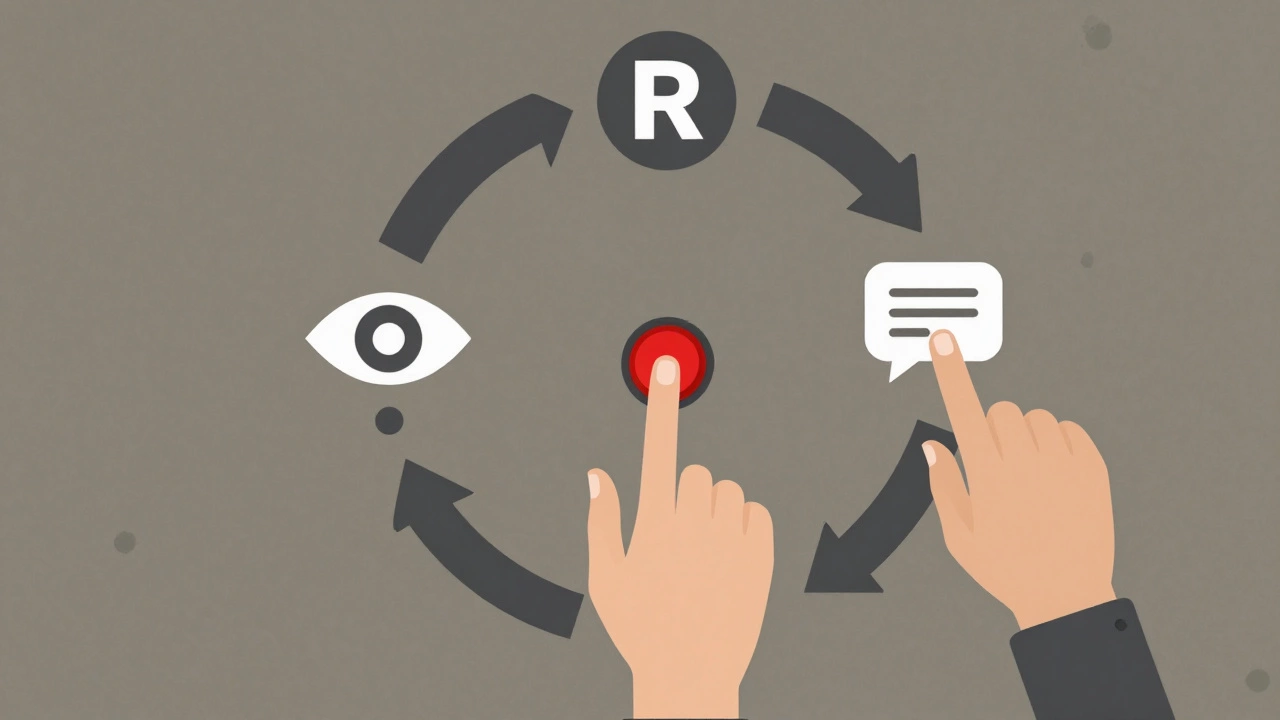

When you walk into any workplace in the UK, you’ll likely see posters about safety. Maybe it’s a construction site, a warehouse, or even an office. One thing you’ll almost always see mentioned is the three R's in safety. But what do they actually mean? And why do they matter so much?

Recognize the Hazard

The first R is Recognize. It sounds simple, but spotting danger isn’t always obvious. A frayed electrical cord, a wet floor without a warning sign, a ladder leaning at the wrong angle - these aren’t accidents waiting to happen. They’re already happening, just slowly.In 2024, the Health and Safety Executive (HSE) reported that over 60% of workplace injuries in the UK started with someone not noticing a risk until it was too late. That’s not bad luck. That’s a failure to recognize.

Recognizing hazards means training your eyes to scan. Not just when something looks wrong, but when something looks normal. Because most hazards don’t scream. They whisper. A loose handrail. A blocked fire exit. A coworker skipping gloves because it’s "just a quick job."

Real example: A kitchen assistant in Bristol noticed steam rising from a faulty boiler valve. No one else saw it as a problem - it had been doing that for weeks. She reported it. Turns out, the valve was about to burst. That’s recognizing a hazard before it becomes an incident.

Reduce the Risk

Once you see it, you can’t just shrug and walk away. The second R is Reduce. This is where action starts. It’s not about waiting for a manager to fix it. It’s about doing what you can, right then.Reduction doesn’t always mean expensive gear or major changes. Sometimes it’s as simple as moving a box off a walkway. Or putting up a cone. Or turning off a machine before cleaning it. The HSE’s 2023 Workplace Safety Report found that 78% of preventable accidents were stopped by immediate, low-cost actions taken by frontline workers.

Think of it like this: you wouldn’t wait for a doctor to arrive before putting pressure on a bleeding wound. Same here. If you see a spill, grab a mop. If a tool is broken, tag it. If a procedure feels unsafe, say so. Reduction is about control - taking back power over your environment.

One warehouse in Bristol started a "Red Flag System" where any worker could place a red sticker on anything that felt risky. Within three months, near-misses dropped by 40%. No new equipment. No new policy. Just people trained to reduce risk, not ignore it.

Report It

The third R is Report. And this is where most safety programs fail. People recognize the hazard. They even reduce it. But they don’t report it. Why? Fear. Confusion. Thinking "someone else will do it."Reporting isn’t about tattling. It’s about creating a safety record. Every report adds data. That data tells managers where the real problems are. Without it, safety becomes guesswork.

Under UK law, employers must have a system for reporting hazards. But systems are useless if no one uses them. A 2024 survey of 2,000 UK workers found that 37% had seen a hazard they didn’t report - mostly because they didn’t know how, or thought it wouldn’t make a difference.

Good reporting is specific. Not: "Something’s wrong." But: "The guard on the conveyor belt at Station 3 is missing. It’s been like this since Tuesday. I saw someone almost get caught in it yesterday."

Companies that make reporting easy - anonymous apps, simple forms, quick response times - see fewer accidents and more trust. Workers feel heard. And when workers feel heard, they speak up sooner.

Why the Three R's Work Better Than Rules

Most safety training dumps a long list of rules on you: "Wear PPE," "Don’t run," "Follow lockout procedures." But rules don’t stick. They’re forgettable.The three R's work because they’re a process - not a checklist. They turn safety from something you’re told to do into something you do naturally. It’s a habit loop: See it. Fix it. Tell others.

It’s also scalable. Whether you’re in a factory, a school, or a care home, the three R's apply. A nurse sees a wet floor? Recognize. Put down a mat? Reduce. Tell the cleaning team? Report. Same steps. Same outcome.

And it’s human. You don’t need a degree to understand it. You just need to care enough to look.

What Happens When You Skip One R?

Missing one of the three R's breaks the chain.Let’s say you recognize a frayed cable. You report it. But you don’t reduce it. You assume someone else will fix it. Meanwhile, someone plugs in a heater. The cable sparks. Fire. Injury.

Or you reduce it - you unplug the machine. But you don’t report it. The next person comes along, plugs it back in. The hazard returns. No one knows why it happened before.

And if you just report without recognizing? You’re sending in noise. A vague complaint. No context. It gets ignored.

Each R depends on the one before. Skip one, and safety collapses.

How to Teach the Three R's to Your Team

If you’re a supervisor, trainer, or just someone who cares about safety, here’s how to make the three R's stick:- Start every safety meeting with a real example - not a textbook. "Last week, Maria saw this. What would you have done?"

- Use photos. Show actual hazards from your workplace. Blur names, but not the risk.

- Practice. Do a 5-minute "hazard hunt" during your shift. Find one thing. Reduce it. Report it.

- Make reporting easy. Use a QR code on the wall that links to a one-click form.

- Thank people who report. Publicly. Even if it’s just, "Thanks for catching that. You kept us safe."

Don’t just hand out a poster. Make it part of how you talk, every day.

Real Impact: Numbers Don’t Lie

A manufacturing plant in Coventry rolled out the three R's training in early 2024. They didn’t buy new machines. They didn’t hire a safety consultant. They just taught the three R's - and practiced them daily.Within six months:

- Reported hazards increased by 120%

- Accidents dropped by 58%

- Employee satisfaction with safety jumped from 52% to 89%

That’s not magic. That’s clarity. When people know exactly what to do - and why - they do it.

Final Thought: Safety Is a Habit, Not a Policy

The three R's aren’t a government requirement. They’re a mindset. And that’s why they last.You won’t remember every rule from your last safety course. But if you learn to recognize, reduce, and report - you’ll carry that with you for life. In work. At home. Even when you’re fixing your bike or helping your kid climb a tree.

Safety isn’t about compliance. It’s about care. And the three R's? They’re the simplest, most powerful way to show it.

Write a comment