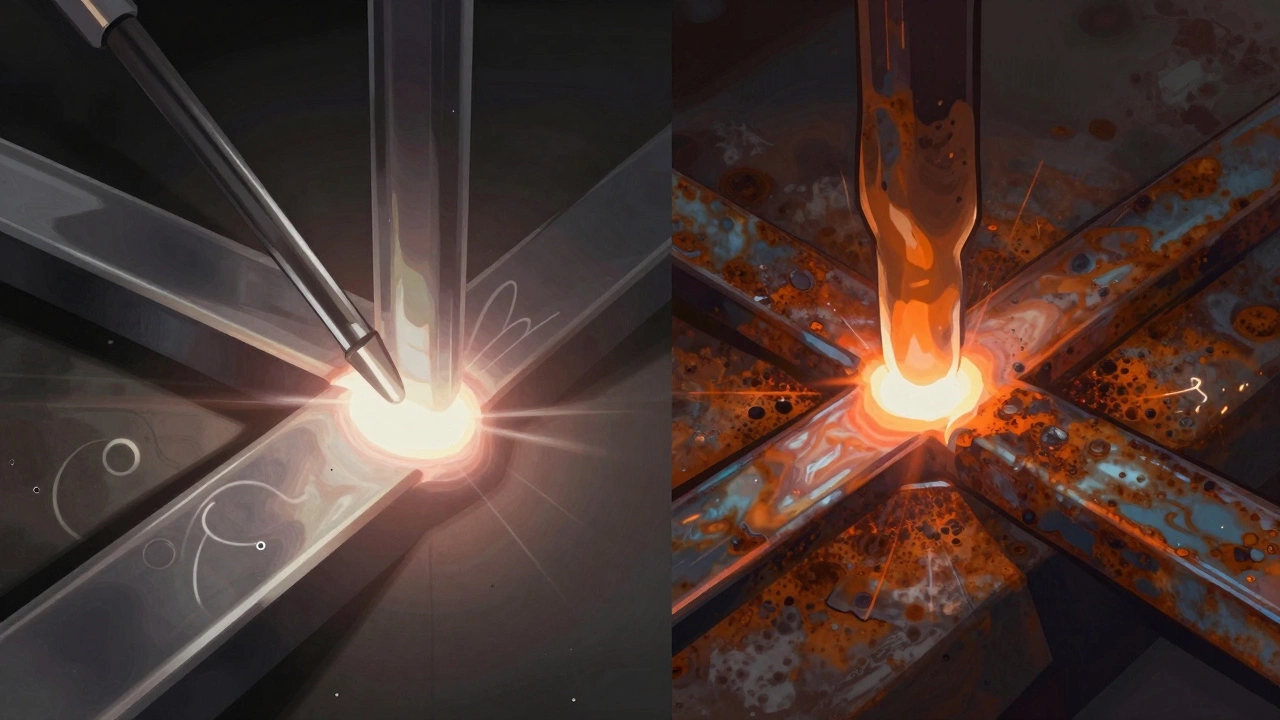

When you hear someone say 7018 is stronger than MIG welding, they’re mixing up tools with materials. It’s like asking if a hammer is stronger than a screwdriver. One isn’t better than the other-they do different jobs. But if you’re trying to pick the right weld for a job, especially in construction or heavy fabrication, knowing the real difference between 7018 electrodes and MIG welding matters. A lot.

What is 7018 welding?

7018 is a type of stick electrode-also called shielded metal arc welding (SMAW). The "70" means it produces a weld with a minimum tensile strength of 70,000 psi. The "1" means it can be used in all positions: flat, horizontal, vertical, and overhead. The "8" tells you it has a low-hydrogen flux coating that gives you smooth, strong welds with good impact resistance, even in cold weather.

Welders in bridge construction, shipyards, and pipeline work rely on 7018 because it’s tough. It doesn’t crack easily under stress. In fact, the American Welding Society (AWS) requires 7018 for structural steel applications where ductility and toughness are critical. You’ll see it used on steel beams, pressure vessels, and crane components. The slag it leaves behind is easy to chip off, and the arc is stable-even on rusty or dirty metal.

What is MIG welding?

MIG, or Metal Inert Gas welding, is also called GMAW-Gas Metal Arc Welding. It uses a continuous wire feed and a shielding gas (usually argon or a mix) to protect the weld pool. MIG is faster, cleaner, and easier to learn than stick welding. That’s why it’s popular in auto repair shops, fabrication labs, and DIY garages.

The wire you feed through the gun can be made of different alloys. Common ones are ER70S-3 and ER70S-6, which also produce 70,000 psi tensile strength. So right away, you can see the numbers match up. But strength isn’t just about the number on the label. It’s about how the weld behaves under load, how it handles stress, and whether it cracks when cooled or bent.

Strength comparison: 7018 vs MIG wire

Both 7018 electrodes and ER70S-6 MIG wire are rated for 70,000 psi tensile strength. That’s the baseline. But here’s where people get fooled:

- 7018 welds have better impact resistance at low temperatures. In sub-zero conditions, MIG welds can become brittle. 7018 doesn’t.

- MIG welds are faster to make, but they can trap gas if the shielding is poor. That creates porosity-tiny holes that weaken the weld.

- 7018’s slag coating protects the weld as it cools, reducing porosity and cracking. MIG needs perfect gas flow and clean metal to avoid defects.

- 7018 handles dirt, rust, and paint better. MIG requires clean, bare metal. If you’re welding an old steel beam with surface rust, 7018 wins.

So yes, 7018 is stronger in real-world conditions-not because the number is higher, but because it’s more forgiving and more reliable under stress, vibration, and temperature swings.

When to use 7018

Use 7018 when:

- You’re welding structural steel for buildings, bridges, or cranes

- The job is outdoors in wind or cold weather

- The metal is dirty, painted, or slightly rusty

- You need high toughness and crack resistance

- You’re working on a project that must pass ASME or AWS D1.1 inspections

These are not hobbyist tasks. They’re professional, code-required welds. In fact, many welding certifications (like AWS Certified Welder) test candidates on 7018 for this reason. It’s the gold standard for structural integrity.

When to use MIG

MIG is better when:

- You’re welding thin sheet metal-like car panels or HVAC ducts

- You need speed and efficiency-like in a production line

- You’re new to welding and want to learn without struggling with electrode manipulation

- The metal is clean and you have good gas shielding

- You’re doing repairs on farm equipment or trailers

MIG doesn’t need slag removal. It’s cleaner, faster, and leaves less mess. That’s why it dominates in automotive and light fabrication. But if you try to use MIG on a load-bearing beam with surface rust, you’re asking for trouble.

Real-world example: Welding a steel bridge

Imagine you’re welding the girders of a pedestrian bridge in northern England. It’s November. It’s been raining. The steel is damp. Wind blows across the site. You’ve got 8 hours to complete the welds before the crane moves in.

You grab a MIG gun. You set the gas flow. You clean the joint as best you can. But the wind picks up. The shielding gas gets blown away. You get porosity. You go back and grind it out. You re-weld. Now you’re behind.

Now imagine you use 7018. You strike the arc. The flux coating shields the weld. The wind doesn’t matter. You don’t need gas. The slag covers the weld as it cools. You get a clean, strong bead. No grinding. No rework. You finish on time.

That’s why 7018 is still king in heavy construction. Not because it’s "stronger" on paper. Because it works when things go wrong.

Can you use MIG instead of 7018?

Technically, yes-if you’re not bound by code. But if you’re welding something that must meet structural standards (like a building, crane, or pressure vessel), then no. Code requirements like AWS D1.1 and ASME Section IX often specify 7018 for critical joints. MIG wire might meet the strength number, but it doesn’t always meet the toughness or defect tolerance standards.

Some advanced MIG processes with flux-cored wire (FCAW) can mimic 7018 performance. FCAW-S (self-shielded) doesn’t need external gas and works in wind. But even then, the filler metal must be rated as E70T-1 or similar to match 7018’s properties. It’s not the same as using standard MIG wire.

What about welding position?

7018 works in all positions. MIG is easiest in flat and horizontal. Vertical-up MIG is possible but tricky. You need to slow down, use the right wire speed, and control the puddle. Many welders avoid vertical MIG because it’s harder to control than stick.

That’s why 7018 is still the go-to for overhead welds on structural steel. You can lay down a clean, strong bead without the puddle falling out.

Cost and skill difference

MIG machines cost more upfront. A good MIG welder runs $800-$1,500. A basic stick welder? $300-$600. 7018 electrodes cost about $10-$15 per pound. MIG wire is $15-$25 per pound, plus shielding gas ($30-$50 per cylinder).

But the bigger difference is skill. 7018 requires more technique. You need to strike the arc, maintain the right length, and chip slag. MIG is plug-and-play. Push the trigger, move the gun. That’s why MIG is the first thing taught in beginner welding courses. But if you want to work on serious projects, you’ll need to master 7018.

Final answer: Is 7018 stronger than MIG welding?

No-7018 isn’t stronger than MIG welding. But 7018 electrodes produce stronger, more reliable welds in demanding environments. MIG is faster and easier, but it’s more sensitive to conditions. If you need a weld that survives cold, wind, dirt, and heavy stress, 7018 wins. If you’re fixing a lawnmower or building a garden shed, MIG is fine.

Strength isn’t just about numbers. It’s about consistency, toughness, and how well the weld holds up when things go wrong. That’s why professional welders don’t choose based on what’s "stronger" on paper. They choose based on what works when the job matters.

Is 7018 better than MIG for outdoor welding?

Yes. 7018 doesn’t need shielding gas, so wind won’t blow away the protection. MIG requires clean gas flow, which fails in breezy conditions. That’s why 7018 is standard for outdoor structural work.

Can MIG wire match the strength of 7018?

Yes, ER70S-6 MIG wire has the same 70,000 psi tensile strength rating. But 7018 welds typically have better impact resistance and fewer defects like porosity, especially on imperfect metal.

Do I need a special welder for 7018?

No. Any stick welder will do. You don’t need gas, and even basic machines handle 7018 well. MIG requires a wire feeder and gas tank, which adds complexity and cost.

Why do welding certifications test 7018?

Because 7018 is the industry standard for structural welding. Passing a 7018 test proves you can make reliable, code-compliant welds under real conditions-not just clean lab setups.

Is MIG welding good for beginners?

Yes. MIG is easier to learn because it’s automatic. You don’t need to strike an arc or control slag. It’s the best starting point for new welders before moving on to stick or TIG.

What’s next for your welding skills?

If you’re serious about construction welding, learn 7018. It’s not just another electrode-it’s the benchmark. Take a course that includes structural welding certification. Practice on scrap steel. Try welding on rusty pipe, then clean plate. Feel the difference.

Don’t just chase the strongest weld. Chase the most reliable one. That’s what matters when lives and structures depend on it.

Write a comment